Pangun FMEA

Software Tools

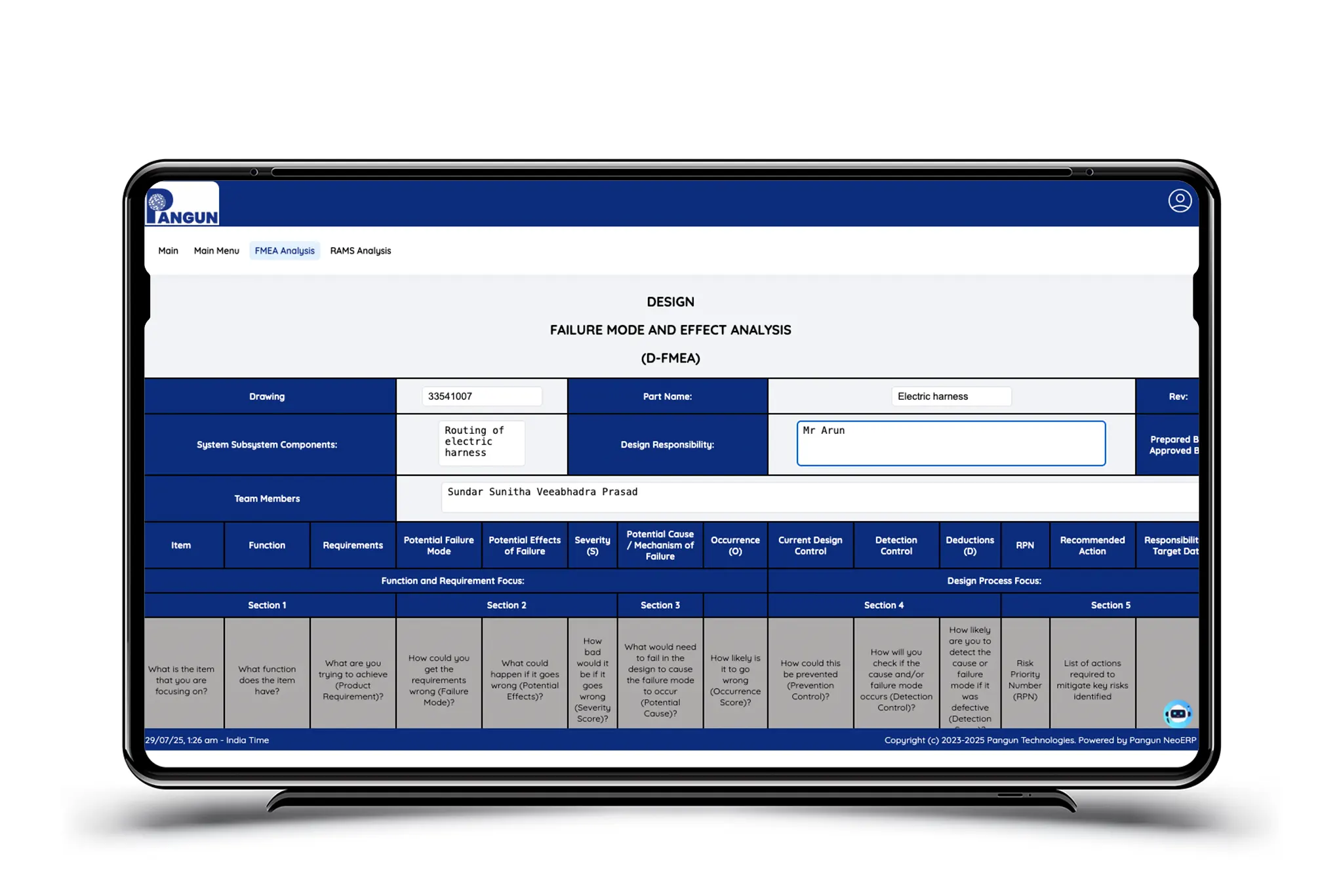

Pangun FMEA Software Tool identifies failures, evaluates risks and prevents issues.

Pangun FMEA Tool streamlines failure analysis with a built-in reporting tool, bringing visibility and control to product systems, sub-systems, etc. computing risk priority across the lifecycle.

It takes input from 8D analysis and guides the teams through structured risk analysis—capturing potential failure modes, their effects and causes, and prioritizing them based on severity, occurrence, and detection. It enables proactive decision-making and timely action planning across both design and manufacturing, reducing failures and improving overall product reliability.

FMEA also supports industry-specific audit readiness by providing a structured and traceable record of risk assessment and mitigation activities. FMEA is a key requirement for the Aerospace & Defence, Railways, Oil and Gas, Automotive & UAV industry.

FMEA can be used as an input for RAMS and Design & Development/Process.

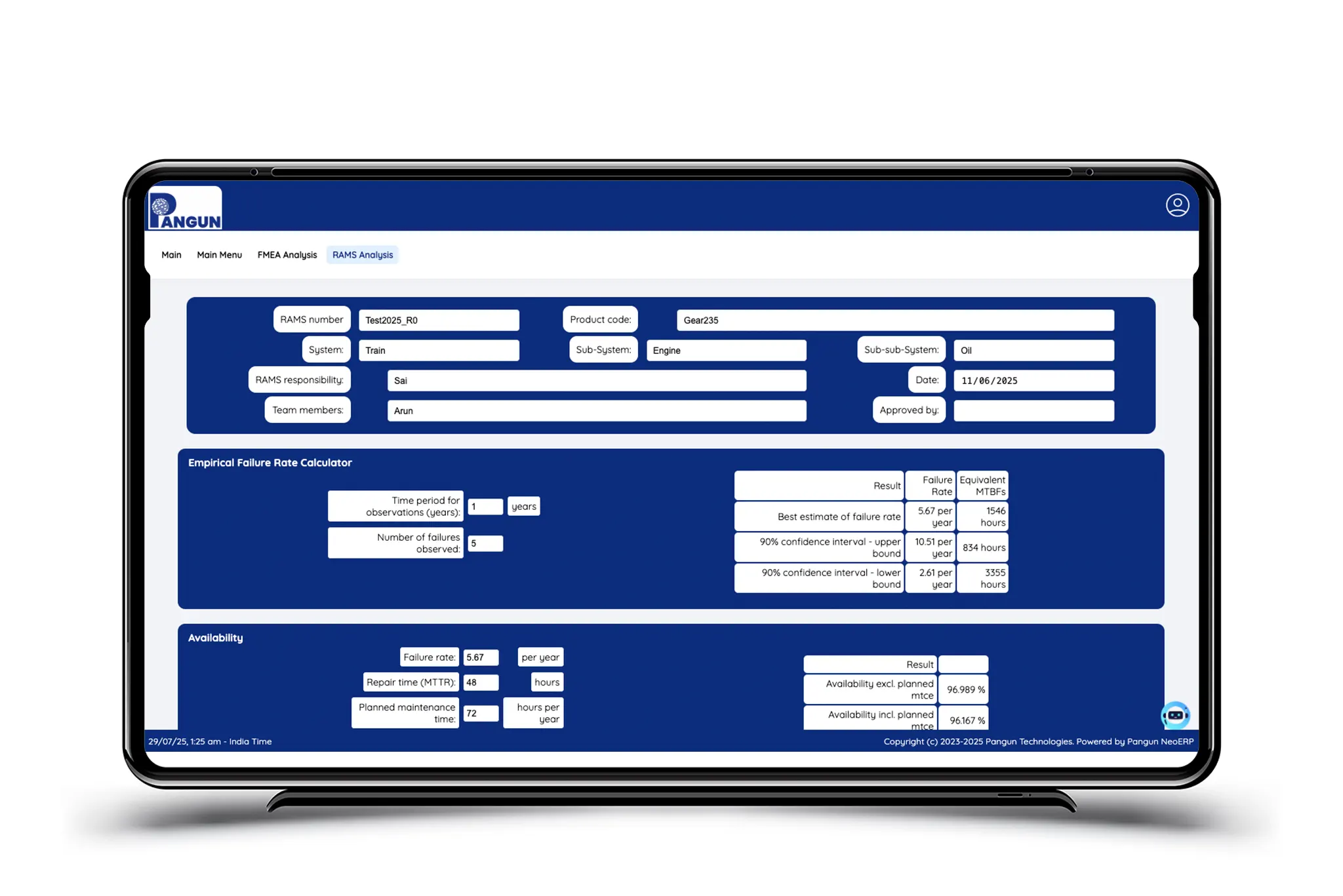

Pangun RAMS Tool delivers an integrated solution for Reliability, Availability, Maintainability, and Safety analysis—essential for industries where safety standards, system uptime, and compliance audits are critical. It proactively manages lifecycle performance and minimizes operational risks.

The tool computes failure rates along with confidence intervals and evaluates key metrics such as MTBF (Mean Time Between Failures) for reliability, MTTR (Mean Time to Repair) for maintainability, and computes overall availability. These insights enable informed decisions on design improvements, maintenance strategies, enhance safety and control risks.

By aligning with industry-specific audit requirements, it enhances audit readiness while supporting system integrity, safety and operational excellence. RAMS is a key requirement for the Aerospace & Defence, Railways, Oil and Gas, Automotive & UAV industry.

RAMS can be used as an input for LCC and FMEA.

Optimized capital investment decisions, reduced total cost of ownership, improved budget forecasting, and enhanced asset strategy development.

Transform failure data into improvement opportunities with our Failure Reporting, Analysis, and Corrective Action System.

Pangun FRACAS Tool provides a comprehensive closed-loop failure management system that captures, analyses, and resolves both in-house and field failures—making it indispensable for industries where traceability, reliability, and safety are paramount.

The tool unifies field failure data and in-house trial results into a structured analysis framework. It enables systematic failure logging, root cause analysis, and automated CAPA tracking. Key metrics like MTBF and MTTR are computed to monitor RAMS trends. Failures are traceable to part numbers, subsystems, and vendors, enabling teams to reduce recurrence, enhance design, and drive continuous improvement.

It ensures audit-ready records align with industry standards such as AS9100, IRIS, and API. Built-in dashboards and traceable histories support compliance requirements and simplify preparation for quality and safety audits.

FRACAS is a key requirement for the Aerospace & Defence, Railways, Oil and Gas, Automotive & UAV industry.

Pangun’s Life Cycle Cost (LCC) Tool empowers manufacturers to make data-driven maintenance and procurement decisions by analysing long-term cost implications of component usage. It enables cost forecasting across a product’s entire service life.

The tool calculates preventive maintenance costs by factoring in each part’s specification, raw material, price, life span, number of replacements over the years, and quantity per system. With this structured approach, organizations can identify cost-intensive components, compare sourcing options, based on LCC optimize the design for durability using FMEA, and plan budgets effectively—ultimately reducing total ownership cost and enhancing operational efficiency.

LCC is important for cost management and audits in the Aerospace, Automotive, and UAV industry & is a critical document in Oil & Gas, Railways, and Defence industry. It helps evaluate long-term cost implications of systems and components. LCC is a key requirement in these industries for procurement, maintenance, and compliance decisions.

LCC can take inputs from RAMS and give output to FMEA.

Pangun RCA (8D) Tool offers a disciplined approach to root cause analysis using the globally recognized Eight Disciplines (8D) method—crucial for manufacturers in aerospace, defence, railways, automotive, UAV & Oil & Gas and other high-reliability industries.

The tool systematically guides users through all 8D steps: preparation and team formation, detailed problem description, interim containment action, root cause and escape point identification, selection and implementation of permanent corrective actions, and measures to prevent recurrence. It also supports team acknowledgment. Integrated CAPA tracking, built-in forms, and dashboards ensure traceability and faster resolution.

The system supports compliance with industry standards such as AS9100, IRIS, and API, enhancing audit readiness and documentation quality.

8D analysis can take inputs from the FRACAS tool and then feed the result into the FMEA tool.

Proactive risk mitigation, increased workplace safety, regulatory compliance, and streamlined decision-making.

Visualise and score risks, track mitigation strategies, and ensure clear ownership of controls.

Proactive risk mitigation, increased workplace safety, regulatory compliance, and streamlined decision-making.

Visualise and score risks, track mitigation strategies, and ensure clear ownership of controls.

Improved measurement accuracy, ISO compliance, reduced downtime, and full traceability of equipment performance.

Automate calibration alerts, store certificates, and ensure traceable records for all critical instruments.